This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

4.5”, 6”, 10” and 14” Structural Sealing Clamps for PAG

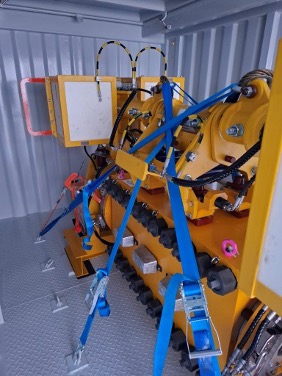

We have been contacted by a major to deliver repair clamps to CNOOC in China as the end customer. The clamps were meant to be stored as an EPRS and the scope consisted of 4 split structural sealing clamps for 4.5”, 6”, 10” and 14” rigid flowlines. All the clamps were designed for high pressure and ultra deep water (2000 m).

All the clamps consisted of double compression packers to ensure complete sealing of a potential leakage area and, for structural support, gripping elements able to withstand full end cap loads. The four clamps were designed for ultra-deep water and high pressure, and each clamp had its own installation frame with buoyancy elements attached. Both assembly and testing took place in Norway.

To meet the end customer’s requirement for DNV type approval, we successfully obtained certifications for all clamps. This not only validated the design’s functionality and the efficiency of our manufacturing and testing processes but also streamlined future orders and design iterations.

As the solution was delivered under an EPRS scope, installation could potentially occur over an extended timeframe. To address this, we designed custom containers not only for safe transport but also for long-term storage of the clamps. Additionally, our engineers provided hands-on training to the client’s specialists, covering operation, basic maintenance, and installation coordination, and enabling the customer to respond swiftly when required.

The clamps were successfully designed, manufactured, and delivered on time and within budget. This project highlights our ability to respond efficiently to complex requirements. It reinforces our commitment to customer support, not only during the design and delivery phases, but also with a strong focus on long-term operational readiness. Our proactive approach and attention to lifecycle needs demonstrate the value we bring as a trusted partner in EPRS projects.